High performance with flexibility

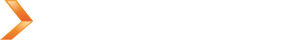

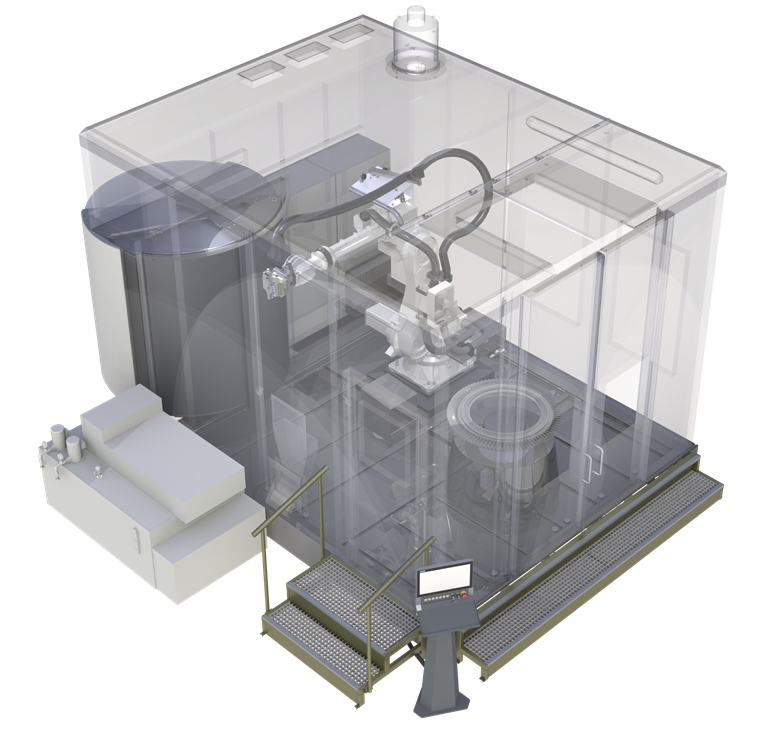

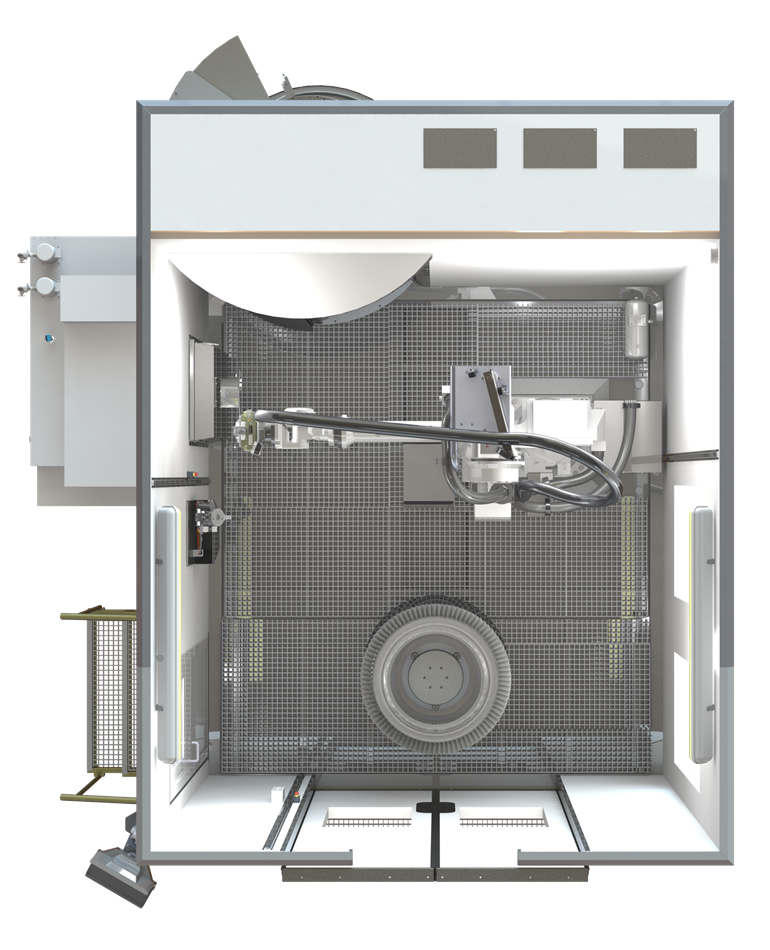

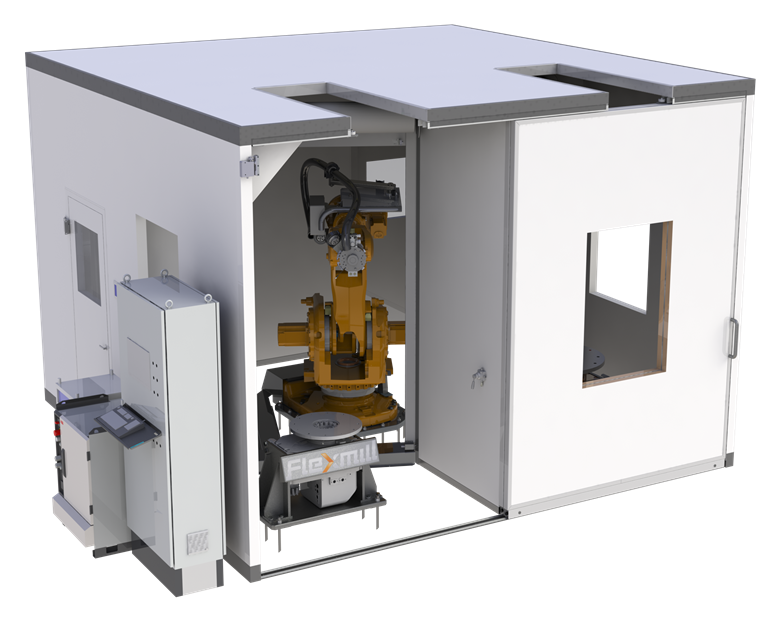

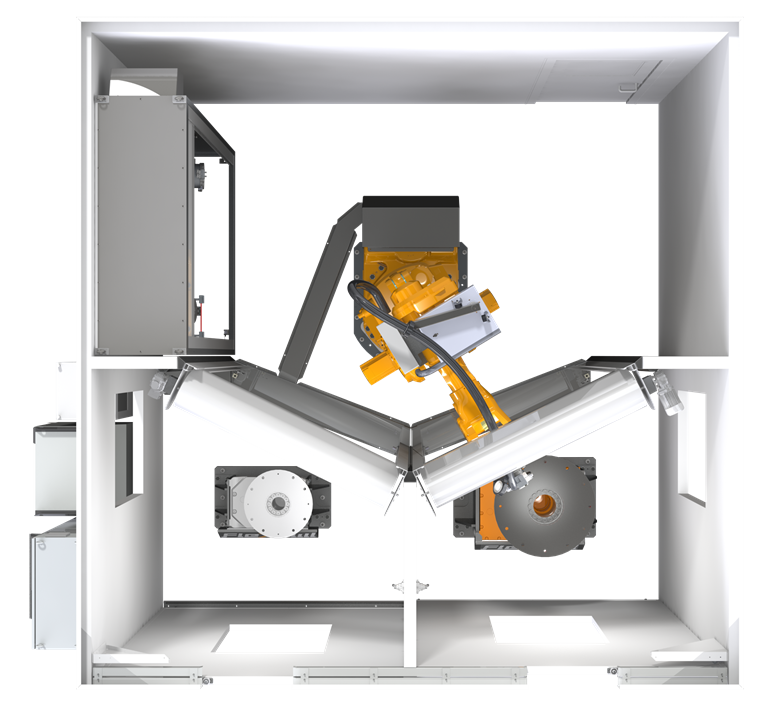

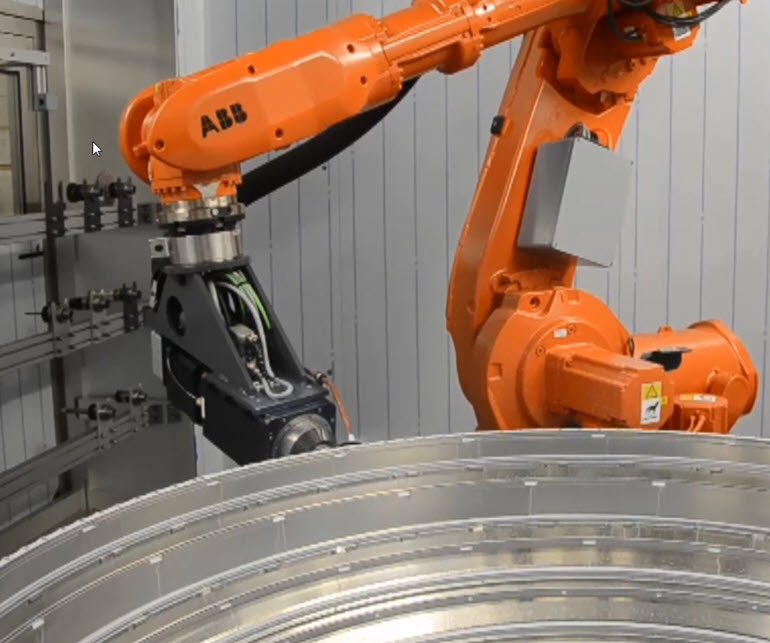

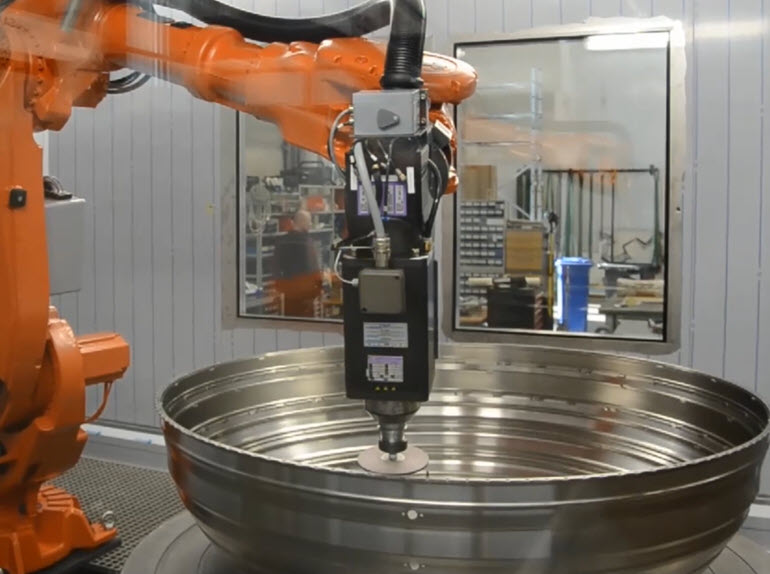

Flexmill’s L-series is a solution for larger work pieces. It offers flexibility to utilize the platform for numerous difference applications by combining a wide range of available standard tools and process modules.

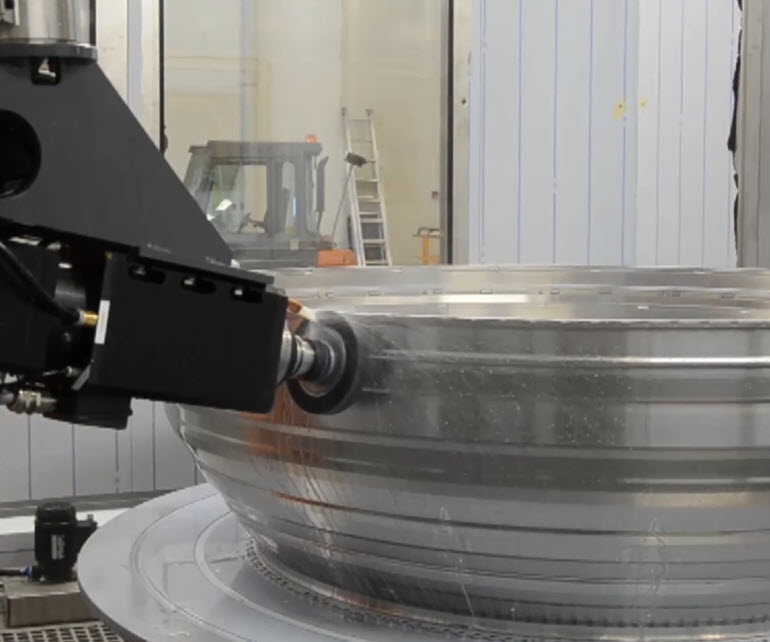

Depending on the desired application, the L-series can be equipped for either dry or wet proceessing conditions. With wet processing conditions, the base structure includes a coolant fluid collection pool.

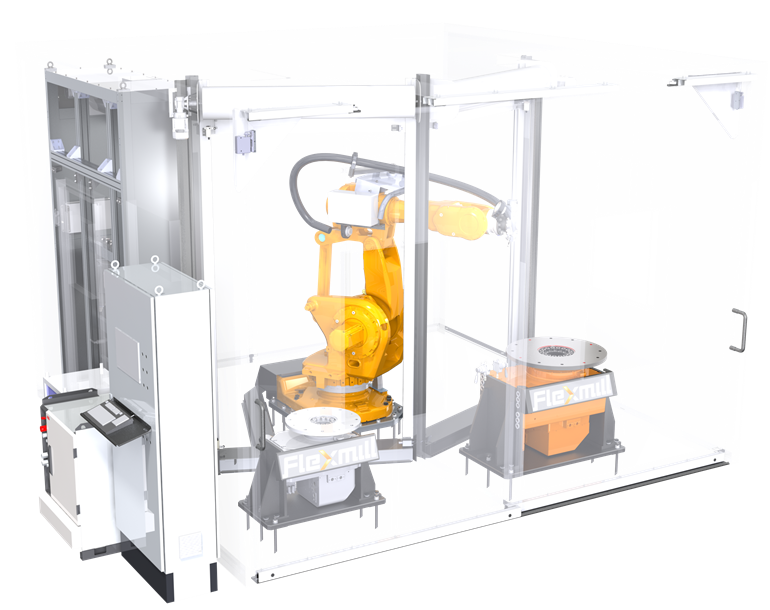

Flexmill’s L-series robot cell offers a flexible and scalable machine design that suits a variety of different manufacturing environments. The level of automation can be scaled from the semi-automatic manually operated machine to a fully automatic production cell for automated FMS lines.

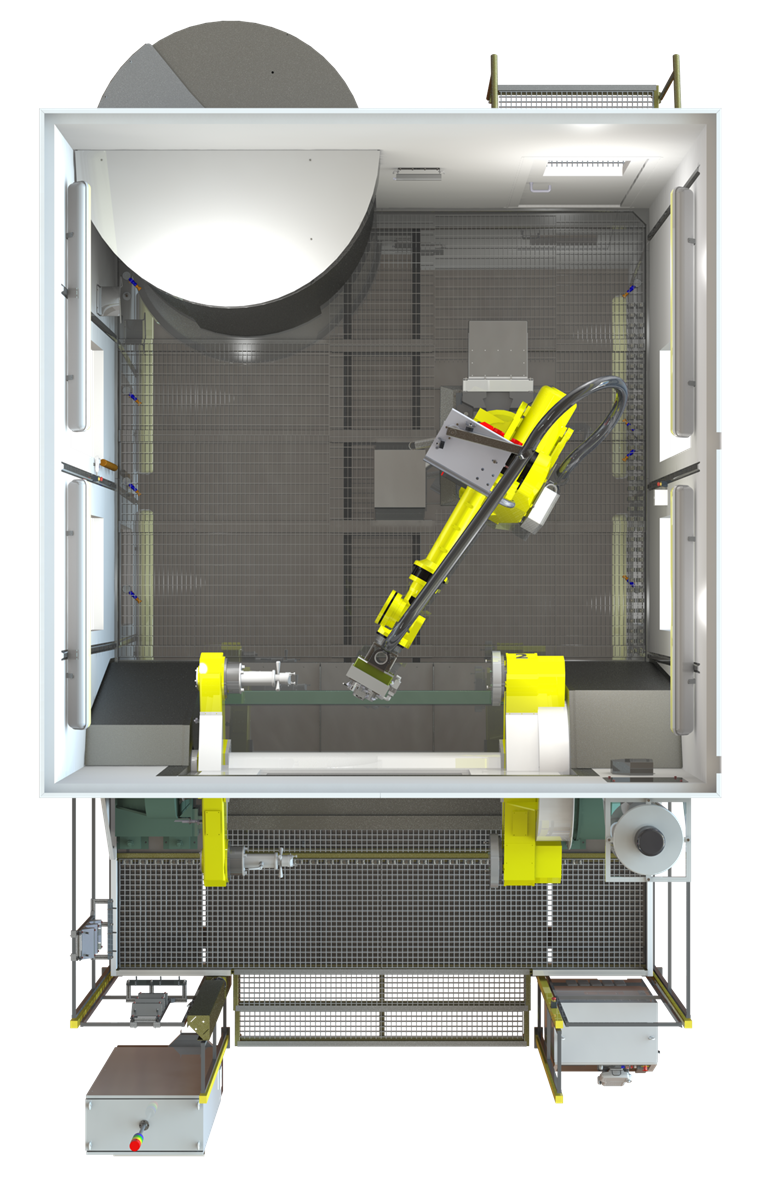

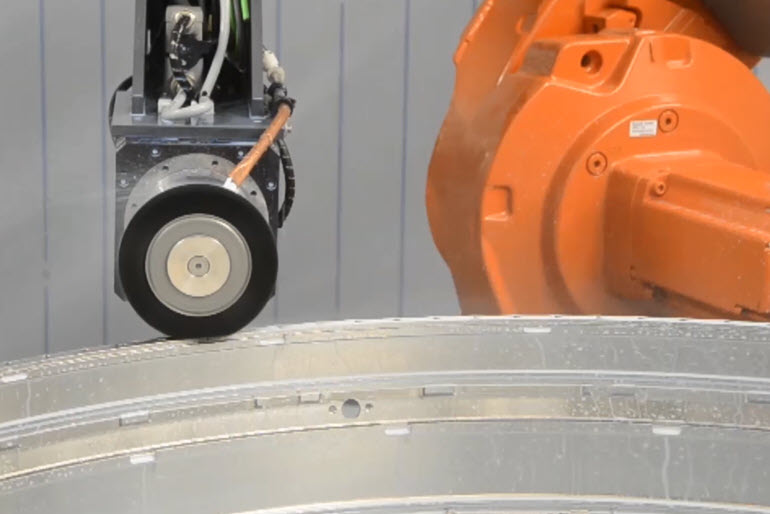

The working principle of the L-series is always the from tool to part method. A wide range of available standard tools and application-specific tools can be stored in different types of tool cabinets providing long unmanned process times for machine cells. The L-series solution can be also equipped with the patented disk media change system in order to prevent interruptions in work in progress.

Standard configurations available for:

- Blade and vane polishing / finishing

- Blisk polishing / finishing

- Large casings deburring and grinding

- Big structure deburring and grinding

- Gear chamfering

- Propeller finishing

- Weld grinding

- Laser marking