Why Flexmill?

We develop intelligent robotic surface finishing solutions for system integrators and manufacturers in industries such as aerospace, marine, energy, and steel fabrication. We have delivered more than 100 systems to 70+ companies in 20 countries. World-leading industrial brands such as Rolls Royce, Wärtsilä, Collins Aerospace, and GKN trust Flexmill when robotizing their surface finishing operations.

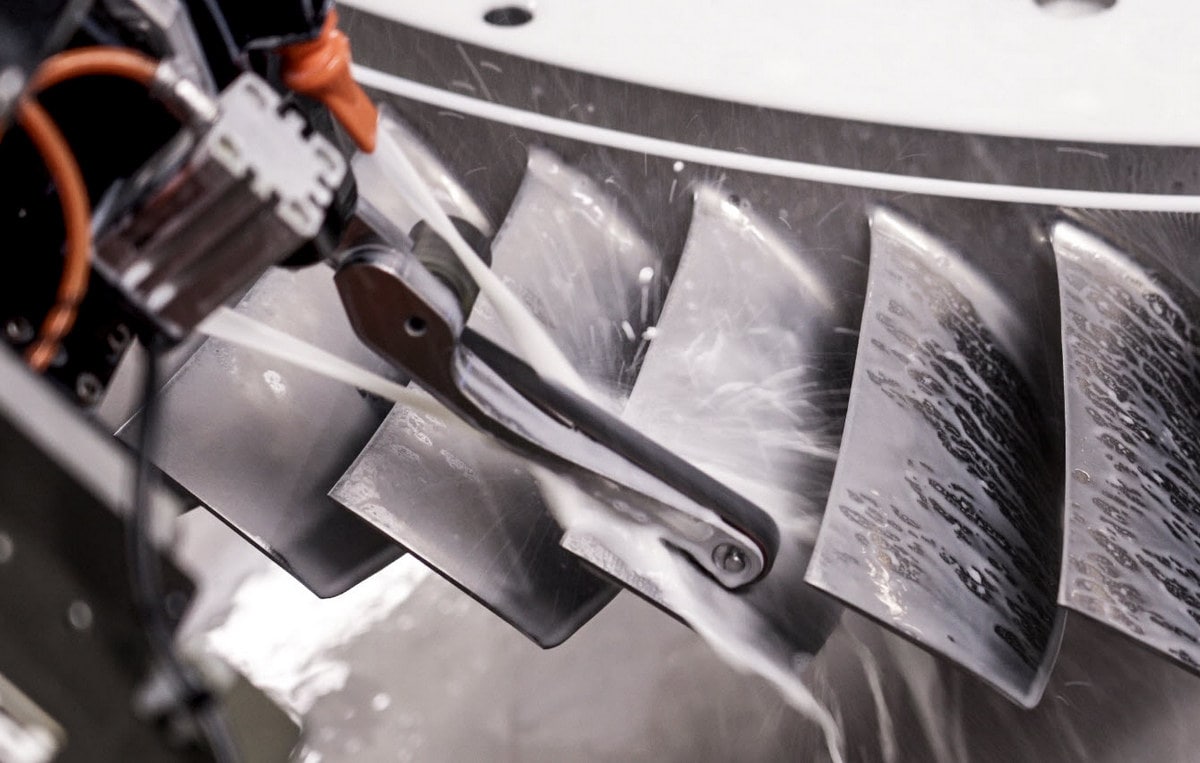

Flexmill is renowned for its unique combination of robotics, machine vision, sensors, and software. The modular Flexmill platform reduces your investment and ordering time, yet it allows an optimally tailored and scalable solution for every customer’s need.

Our customers highly appreciate the benefits of our unique innovations – such as the patented, fully automatic belt and disc changer, which maximizes their grinding robot’s unmanned operation time. The tool time manager software tracks tool use and triggers tool change at the end of its lifecycle. Surface grinding won’t get more automated! Our cutting-edge force and compliance unit ensures a smooth and uniform surface across all workpieces.

However, mastering technology is not yet enough to build efficient grinding solutions. We have extensive, in-depth knowledge of tools and processing methods for most materials, geometries, and applications. We have worked side-by-side with integrators and manufacturers for decades and understand their challenges.

Why choose Flexmill? Our in-depth industrial and process knowledge and the most advanced robotic solutions set us apart from the competition and make us your best partner for automated grinding!

Flexmill Benefits

- End-to-end and in-depth industrial process knowhow

- Software-driven solution – Easy usability

- Modular platform tailored for your needs and budget

- Most automated grinding robot with patented, automatic tool changer

- Plug & Play – Minimized investment and fast time-to-production!

- Continuous Support – Scale & upgrade equipment throughout its entire lifespan of up to 15 years